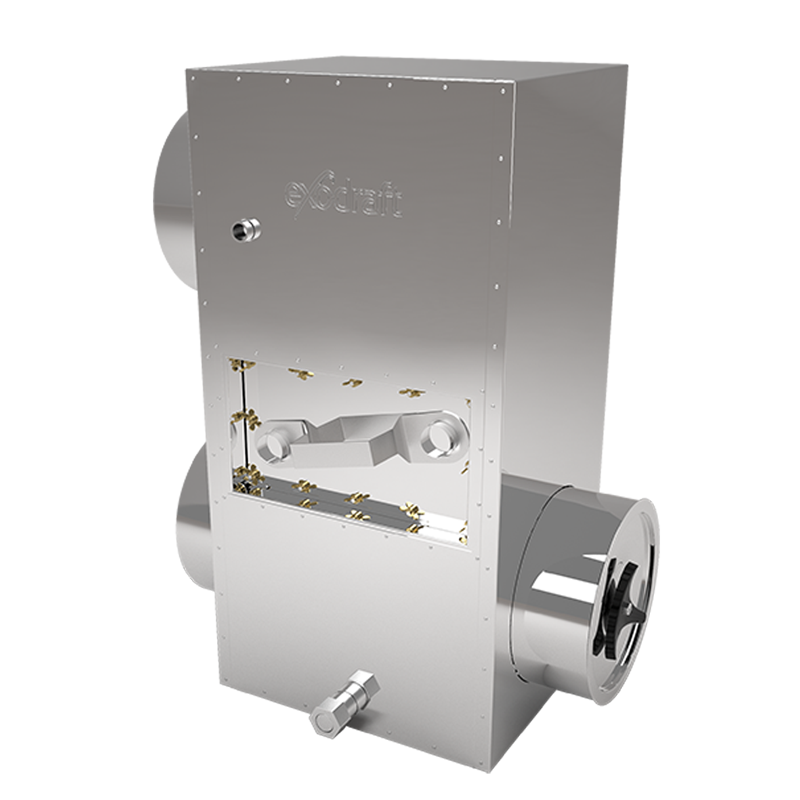

The steam/water vapour heat recovery unit CHR-P-S from exodraft recovers energy in gaseous by bringing water into condensation. Its compact design and high efficiency are made possible by the incorporation of highly efficient plate heat exchangers.

Due to a self-cleaning e ect the inspection intervals of the exodraft heat exchanger is reduced to a minimum.

The housing of the CHR-P-S

The housing of the steam/water vapour heat exchanger CHR-P-S consists of a 2 mm stainless steel 1.4571 and is equipped with a 30 mm thick insulation against heat loss. For the derivation of the condensate, the front panel of the device has a condensate drain. The housing can only operate with low-pressure steam/water vapour.

Through a mutually mountable inspection opening an inspection of the plate heat exchanger is possible without dismantling.

The heat exchanger

The heat exchanger is an industrially manufactured, asymmetric insertion plate heat exchanger. Depending on performance, it consists of up to 140 stainless steel plates which are soldered with copper (standard) or nickel (Optional).

A safety temperature limiter (STB) to protect against overheating of the device must be mounted.

The heat exchanger complies with the Pressure Equipment Directive 97/23/EC-3 and is approved for an operating pressure of up to 16 bar on the liquid side.

Technical Drawings

Need Help?

Chat with our support team today to find the right boiler for your project or to book a service.

Click Here

Our Partners